Mrp erp mecalux meilenstein cdnwm produktionsprozess fabbisogni pianificazione materiali mecaluxde versione milestone process advances

In today's ever-evolving business landscape, implementing efficient production processes is crucial for companies to stay competitive. One such milestone in the production process is Material Requirements Planning, commonly known as MRP. In this article, we will explore the key differences between MRP and Enterprise Resource Planning (ERP) systems, and how they contribute to improving productivity and overall business operations.

MRP: A Production Process Milestone

Material Requirements Planning (MRP) is a production planning, scheduling, and inventory control system that provides manufacturers with valuable insights and tools to efficiently manage their production processes. MRP system software enables companies to plan and organize their material requirements and streamline their production operations.

By utilizing MRP systems, manufacturers can optimize their production schedules, reduce lead times, and ensure the availability of necessary materials to meet customer demands. These systems automate the production planning process, allowing businesses to make more accurate forecasts, manage inventory levels effectively, and minimize wastage.

ERP vs MRP: Enhancing Business Operations

While MRP systems focus primarily on optimizing production processes, Enterprise Resource Planning (ERP) systems encompass a broader range of functionalities. ERP integrates various aspects of a business, including finance, human resources, supply chain management, customer relationship management, and more.

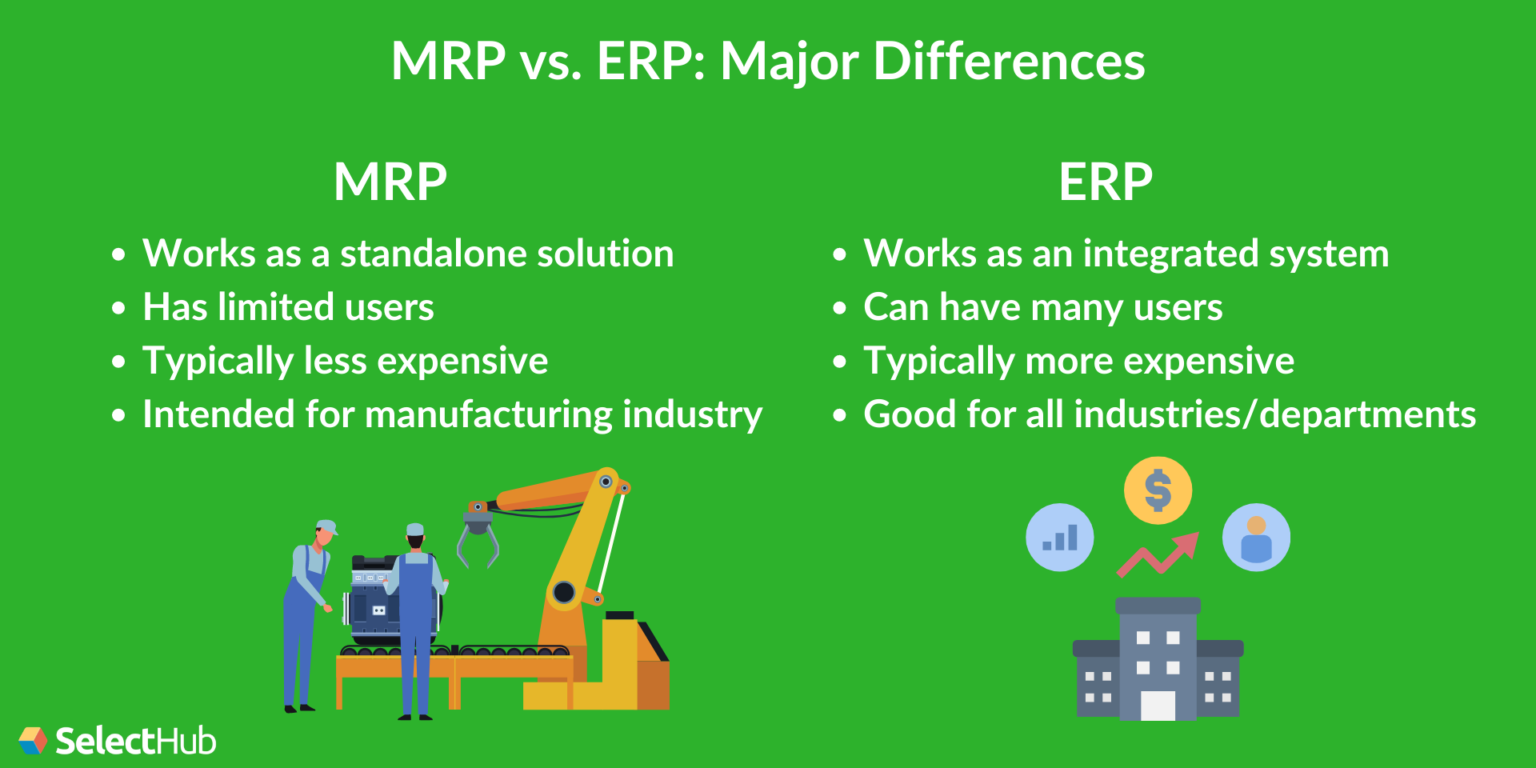

One key difference between MRP and ERP systems lies in their scope. MRP systems are primarily concerned with materials, production planning, and inventory management, whereas ERP systems provide a comprehensive view of the entire business. This enables companies to streamline operations across different departments, improve communication, and foster collaboration.

The Benefits of MRP and ERP Systems

Implementing MRP and ERP systems bring numerous benefits to businesses of all sizes:

1. Enhanced Efficiency and Productivity:

MRP and ERP systems help eliminate manual processes and reduce the chances of human errors. These systems automate various tasks such as purchase order generation, forecasting, and resource allocation, allowing employees to focus on more value-added activities. This enhances productivity and efficiency throughout the organization.

2. Improved Inventory Management:

By accurately tracking inventory levels and demand patterns, MRP and ERP systems ensure that businesses maintain optimal stock levels. This minimizes excess inventory and stockouts, leading to cost savings and improved customer satisfaction.

3. Streamlined Communication and Collaboration:

With ERP systems, different departments within an organization can seamlessly share information, collaborate on projects, and have real-time visibility into business operations. This leads to improved communication, decision-making, and overall organizational performance.

4. Better Customer Relationship Management:

ERP systems enable businesses to centralize customer data, providing a holistic view of customer interactions and preferences. This enhances customer relationship management, allowing companies to tailor their products or services to meet customer needs effectively.

Conclusion

Incorporating MRP and ERP systems into business operations can transform the way companies manage their production processes and overall business activities. While MRP systems focus on optimizing production planning, scheduling, and inventory control, ERP systems provide a broader perspective and integrate various aspects of an organization.

By leveraging the benefits of these systems, businesses can enhance efficiency, streamline communication, improve inventory management, and foster better customer relationships. As the business landscape continues to evolve, investing in MRP and ERP systems is becoming increasingly essential to stay competitive and achieve long-term success.